Thermocouples are suitable for measuring over a

large temperature range, up to 2300 °C. They are less suitable for

applications where smaller temperature differences need to be measured

with high accuracy, for example the range 0–100 °C with 0.1 °C accuracy.

For such applications thermistors and resistance temperature detectors

are more suitable. Applications include temperature measurement for

kilns, gas turbine exhaust, diesel engines, and other industrial

processes.

Types

Certain combinations of alloys have become popular as industry

standards. Selection of the combination is driven by cost, availability,

convenience, melting point, chemical properties, stability, and output.

Different types are best suited for different applications. They are

usually selected based on the temperature range and sensitivity needed.

Thermocouples with low sensitivities (B, R, and S types) have

correspondingly lower resolutions. Other selection criteria include the

inertness of the thermocouple material, and whether it is magnetic or

not. Standard thermocouple types are listed below with the positive

electrode first, followed by the negative electrode.

K

Type K (chromel–alumel) is the most common general purpose

thermocouple with a sensitivity of approximately 41 µV/°C, chromel

positive relative to alumel. It is inexpensive, and a wide variety of

probes are available in its −200 °C to +1350 °C range. Type K was

specified at a time when metallurgy was less advanced than it is today,

and consequently characteristics vary considerably between samples. One

of the constituent metals, nickel, is magnetic; a characteristic of

thermocouples made with magnetic material is that they undergo a step

change in output when the magnetic material reaches its Curie point

(around 354 °C for type K thermocouples).

E

Type E chromel constantan has a high output (68 µV/°C) which makes it

well suited to cryogenic use. Additionally, it is non-magnetic.

J

Type J (iron–constantan) has a more restricted range than type K (−40

to +750 °C), but higher sensitivity of about 55 µV/°C. The Curie point

of the iron (770 °C) causes an abrupt change in the characteristic,

which determines the upper temperature limit.

N

Type N (Nicrosil–Nisil) (Nickel-Chromium-Silicon/Nickel-Silicon)

thermocouples are suitable for use at high temperatures, exceeding

1200 °C, due to their stability and ability to resist high temperature

oxidation. Sensitivity is about 39 µV/°C at 900 °C, slightly lower than

type K. Designed to be an improved type K, it is becoming more popular.

Platinum types B, R, and S

Types B, R, and S thermocouples use platinum or a platinum–rhodium

alloy for each conductor. These are among the most stable thermocouples,

but have lower sensitivity than other types, approximately 10 µV/°C.

Type B, R, and S thermocouples are usually used only for high

temperature measurements due to their high cost and low sensitivity.

- B

Type B thermocouples use a platinum–rhodium alloy for each conductor.

One conductor contains 30% rhodium while the other conductor contains

6% rhodium. These thermocouples are suited for use at up to 1800 °C.

Type B thermocouples produce the same output at 0 °C and 42 °C, limiting

their use below about 50 °C.

- R

Type R thermocouples use a platinum–rhodium alloy containing 13%

rhodium for one conductor and pure platinum for the other conductor.

Type R thermocouples are used up to 1600 °C.

- S

Type S thermocouples are constructed using one wire of 90% Platinum

and 10% Rhodium (the positive or "+" wire) and a second wire of 100%

platinum (the negative or "-" wire). Like type R, type S thermocouples

are used up to 1600 °C. In particular, type S is used as the standard of

calibration for the melting point of gold (1064.43 °C).

T

Type T (copper–

constantan)

thermocouples are suited for measurements in the −200 to 350 °C range.

Often used as a differential measurement since only copper wire touches

the probes. Since both conductors are non-magnetic, there is no Curie

point and thus no abrupt change in characteristics. Type T thermocouples

have a sensitivity of about 43 µV/°C.

C

Type C (tungsten 5% rhenium – tungsten 26% rhenium) thermocouples are

suited for measurements in the 0 °C to 2320 °C range. This thermocouple

is well-suited for vacuum furnaces at extremely high temperatures. It

must never be used in the presence of oxygen at temperatures above 260

°C.

M

Type M thermocouples use a nickel alloy for each wire. The positive

wire contains 18% molybdenum while the negative wire contains 0.8%

cobalt. These thermocouples are used in vacuum furnaces for the same

reasons as with type C. Upper temperature is limited to 1400 °C. It is

less commonly used than other types.

Chromel-gold/iron

In chromel-gold/iron thermocouples, the positive wire is chromel and

the negative wire is gold with a small fraction (0.03–0.15 atom percent)

of iron. It can be used for cryogenic applications (1.2–300 K and even

up to 600 K). Both the sensitivity and the temperature range depends on

the iron concentration. The sensitivity is typically around 15 µV/K at

low temperatures and the lowest usable temperature varies between 1.2

and 4.2 K.

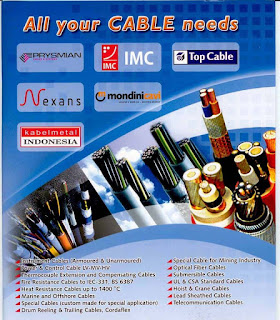

Type of Cables :

-

RT-2Y(St)Yv, RT-Y(St)Yv

-

RT-2Y(St)Yv PiMF, RT-Y(St)Yv PiMF

-

RT-2Y(St)YQY, RT-Y(St)YQY

-

RT-2Y(St)2YSWAY, RT-Y(St)YSWAY

-

RT-2Y(St)2YSWAY PiMF, RT-Y(St)YSWAY PiMF

Applicable Standards : IEC, DIN, VDE, ANSI, JIS,

CV.

MANDIRI KARYA BERSAMA

Kantor : Jl.

Moch Toha , Karawaci, Tangerang

Banten – Indonesia

PIN :

5C54D942 / 59574694

Telp. : 021 –

22252171

Hp : 082210137341,

081316684910, 0895333141311

Email contact

:

elinda.explosionproof@gmail.com

/ sales.mkb1@gmail.com / sales.mkb2@gmail.com

|

|

|